Like many aspects of library cataloguing, controlled vocabulary subject headings hark back to the days of catalogue cards. In those dark before-times, a physical card had to be typed up for each subject heading included in a catalogue record, and filed in boxes with other cards relating to the same subject.

In my opinion, these days controlled subject headings are mainly a search tool for staff with library training. A concise summary or abstract with some juicy keywords thrown in is just as, if not more important for customers searching an online catalogue, especially in a public library setting. Yes, subject headings can provide some keywords for searching, but often they aren't quite in natural language, which means they don't help the general public. After all, who's going to search for "swine" when the generally used word is "pigs"?

Recently I've seen some records on Libraries Australia trying to counteract this by using the 653 MARC field for uncontrolled terms. While I admire cataloguers who strive to make their records more searchable by customers, I'm not sure that this is the solution. Crowdsourced tagging is used on Trove and in some library catalogues, but is it useful to add tags from the back office? After all, the whole point is that tags are not proscribed and have meaning for individual library users. I wonder whether using the 653 field is actually counter-productive, adding more potentially irrelevant search terms to the record.

Public libraries in Australia mostly use Library of Congress Subject Headings (LCSH). The slightly odd terminology and syntax of the taxonomy, coupled with unfamiliar Americanisms and the sometimes frankly bizarre contents of that venerable Library's collection can result in great amusement for cataloguers... Or maybe just for me...

Anyway, here are a few of my picks of the oddest and most LOL-worthy (or at least WTF-worthy) headings I've come across. All screenshots are from the Library of Congress Authorities, which are freely available on the web without a subscription.

Industrial feeding

For me this term conjures up horrific images of force-feeding, but no, it's actually deemed the correct term for cafeterias in industrial settings.

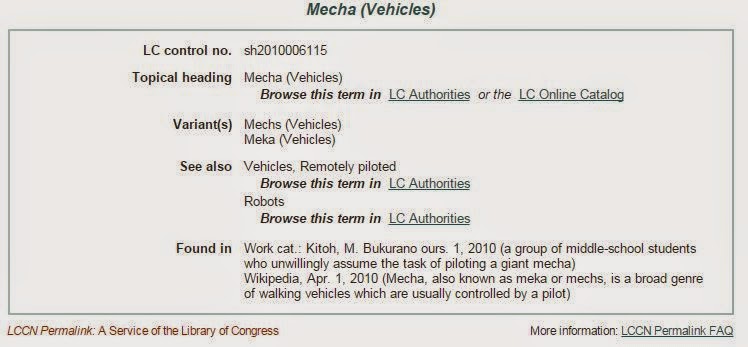

Mecha (vehicles)

I was a HUGE fan of Neon Genesis Evangelion when it came out, so this heading for giant, piloted robots holds a special place in my heart.

African American lesbians in motion pictures

This one falls firmly into the "oddly specific" category. LCSH has headings referring directly to ethnicity, religion and sexuality for almost any subject you can imagine. This could be seen as good (representing the diversity of American society) or bad (perpetuating the American obsession with race and sexual morality) depending on your perspective. See also Lesbians on postage stamps.

Cooking (Semen)

There's a specific source quoted for this authority record, and technically if there's even one work on a subject in the Library, there has to be a subject heading created for it. I'm hoping it ends there, but frankly I don't care to investigate any further.

Animals -- Infancy

A perfectly reasonable heading, in that you would want baby animals to appear as a subdivision of animals as a whole. Unless you're cataloguing kids' DVDs about baby animals. Then it just sounds a bit pompous.

Plus Bonus Name Headings!

2 Chainz

Name authorities for rappers are always great material, but this one takes the cake with its fantastic listing of variant names.

Santa Claus

OK, so technically this is a subject heading, not a name heading. But notice there's no qualifier for "fictitious character." Maybe the staff at the Library of Congress know something we don't...

If you've found a good one that's missing from this list, post it in the comments for our incredibly niche amusement. Now I'm going to end this post with a relevant Youtube video from Yankovic, Al, 1959-

Photo from the UNO Criss Library Flickr stream, taken in 1976

In my opinion, these days controlled subject headings are mainly a search tool for staff with library training. A concise summary or abstract with some juicy keywords thrown in is just as, if not more important for customers searching an online catalogue, especially in a public library setting. Yes, subject headings can provide some keywords for searching, but often they aren't quite in natural language, which means they don't help the general public. After all, who's going to search for "swine" when the generally used word is "pigs"?

Recently I've seen some records on Libraries Australia trying to counteract this by using the 653 MARC field for uncontrolled terms. While I admire cataloguers who strive to make their records more searchable by customers, I'm not sure that this is the solution. Crowdsourced tagging is used on Trove and in some library catalogues, but is it useful to add tags from the back office? After all, the whole point is that tags are not proscribed and have meaning for individual library users. I wonder whether using the 653 field is actually counter-productive, adding more potentially irrelevant search terms to the record.

Public libraries in Australia mostly use Library of Congress Subject Headings (LCSH). The slightly odd terminology and syntax of the taxonomy, coupled with unfamiliar Americanisms and the sometimes frankly bizarre contents of that venerable Library's collection can result in great amusement for cataloguers... Or maybe just for me...

Anyway, here are a few of my picks of the oddest and most LOL-worthy (or at least WTF-worthy) headings I've come across. All screenshots are from the Library of Congress Authorities, which are freely available on the web without a subscription.

Industrial feeding

For me this term conjures up horrific images of force-feeding, but no, it's actually deemed the correct term for cafeterias in industrial settings.

Mecha (vehicles)

I was a HUGE fan of Neon Genesis Evangelion when it came out, so this heading for giant, piloted robots holds a special place in my heart.

African American lesbians in motion pictures

This one falls firmly into the "oddly specific" category. LCSH has headings referring directly to ethnicity, religion and sexuality for almost any subject you can imagine. This could be seen as good (representing the diversity of American society) or bad (perpetuating the American obsession with race and sexual morality) depending on your perspective. See also Lesbians on postage stamps.

Cooking (Semen)

There's a specific source quoted for this authority record, and technically if there's even one work on a subject in the Library, there has to be a subject heading created for it. I'm hoping it ends there, but frankly I don't care to investigate any further.

Animals -- Infancy

A perfectly reasonable heading, in that you would want baby animals to appear as a subdivision of animals as a whole. Unless you're cataloguing kids' DVDs about baby animals. Then it just sounds a bit pompous.

Plus Bonus Name Headings!

2 Chainz

Name authorities for rappers are always great material, but this one takes the cake with its fantastic listing of variant names.

Santa Claus

OK, so technically this is a subject heading, not a name heading. But notice there's no qualifier for "fictitious character." Maybe the staff at the Library of Congress know something we don't...

If you've found a good one that's missing from this list, post it in the comments for our incredibly niche amusement. Now I'm going to end this post with a relevant Youtube video from Yankovic, Al, 1959-